Mushroom, kombucha and algae might sound like a list of ingredients for a health-conscious recipe, but these living organisms are the source of a new wave of sustainable biofabrics. From plant-based leather to lab-grown silk, TheHomeGround Asia explores a buffet of planet-friendly materials that looks set to revolutionise the fashion industry.

Earth Month (April) may be over but that does not mean we should slack off on our sustainability efforts. Indeed, at the risk of sounding trite, in the age of climate change, every day ought to be Earth Day and everyone ought to do their part to protect and preserve our planet. It is a responsibility we must not shrug off, given the sizeable ecological footprint of our lifestyles – and especially of our wardrobe choices.

The price of trend-chasing

It is hardly news that the fashion industry (in particular, fast fashion) has a deleterious impact on the Earth. Much ink has been spilled on the environmental cost of our addiction to the low-cost, low-quality runway rip-offs that fast-fashion giants like Zara, H&M, SHEIN and ASOS churn out at breakneck speed. Nevertheless, the statistics are worth reiterating.

According to figures released by the United Nation’s Intergovernmental Panel on Climate Change, the fashion industry accounts for an estimated 10 per cent of global carbon emissions due to its complex supply chains and energy-intensive production processes, and, as a consequence of textile dyeing and treatment, nearly 20 per cent of wastewater worldwide too.

Moreover, the most commonly-used materials in the apparel industry, including polyester and cotton, put a considerable strain on Earth’s natural resources.

Sustainable business network Common Objective calculates that 65 per cent of all garments manufactured are made of synthetic fibres, such as polyester, nylon, elastane and polyurethane (PU), which are exponentially cheaper than natural fibres, but are basically petroleum-derived plastics. In fact, each year, about 342 million barrels of crude oil are exhausted in meeting the demand for these plastic-based polymers. Additionally, these synthetic fabrics shed large amounts of microfibres when washed, exacerbating the problem of plastic pollution in our oceans and waterways.

Natural fibres are not necessarily better for the environment, either.

Take cotton, for example. Although cotton is biodegradable, it is a water-guzzling crop. It takes up to 10,000 litres of water to make a single pair of denim jeans and up to 3,000 litres to make a t-shirt. Cotton cultivation also uses high levels of pesticides and insecticides that can pollute local ecosystems and water supplies, and, in turn, cause adverse health effects in humans.

Meanwhile, the production of real leather (cowhide, lambskin etc.) has not only been accused of fuelling animal cruelty, it also contributes to greenhouse gas emissions, deforestation and toxic chemical pollution. According to the Food and Agriculture Organisation of the United Nations, livestock farming generates around 15 per cent of the world’s total greenhouse gas emissions.

On top of all that, the fashion industry generates around 92 million tonnes of textile waste annually, with the equivalent of a garbage truck of textiles dumped in landfills or burned in incinerators every second. In 2020 alone, Singaporeans tossed out some 137,000 tonnes of textile and leather waste, of which only four per cent was recycled.

In light of these statistics, the question is: What can we do to lighten our fashion footprint? The oft-repeated mantra is ‘buy less, buy better’. That is, as much as possible, avoid the trap of excessive consumerism by purchasing only what you need; sticking to wardrobe staples that you can wear over and over again; and shopping vintage or secondhand. Also, if it is within your means, invest in higher-quality pieces that will last longer, support small, sustainability-driven labels, and opt for renewable materials that have a minimal impact on the environment.

Fortunately, with an ever-growing pool of conscious shoppers clamouring for ethical and eco-friendly clothes, recent years have witnessed a surge in sustainable textile innovations, from plant-based leather to lab-grown silk. Below, we give you a quick rundown of five of the latest developments in the burgeoning field of ‘green’ fabrics.

Mycelium leather

The word ‘fungus’ generally conjures up icky images of mould and decay, but it seems the humble eukaryote is finally getting its turn in the spotlight, thanks to a handful of big-name brands that have bet on a fungal future for fashion.

Mycelium leather is a vegan leather alternative that is rapidly becoming a hot commodity in the industry. This novel biomaterial is composed of mycelium, the expansive underground root system of mushrooms that facilitates the exchange of nutrients, helps break down organic waste matter, enables plants to communicate with one another (it has been described as the ‘wood wide web’), drives carbon sequestration, and more.

At present, the major players in mycelium cultivation are US-based start-ups Bolt Threads Inc., MycoWorks and Ecovative Design.

Artificial substitutes to leather have mushroomed in popularity over the last decade. According to a market research body early last year, the global vegan leather market is expected to increase by nearly 50 per cent between 2019 and 2025. The material is hard-wearing, supple and breathable, making it an attractive alternative for clothing, including footwear and handbags.

How is mycelium leather made?

Fed with agroforestry by-products, such as molasses and sawdust, cultured mycelial cells are grown in proprietary trays under carefully controlled conditions, which induce the filament-like hyphae to tangle together to form homogeneous, hard-wearing sheets of fibre. Once harvested, these mats of mycelium are usually dehydrated, and then tanned, dyed and finished in line with traditional leather-making techniques.

Why is mycelium leather considered sustainable?

Not only is mycelium leather reportedly infinitely renewable and completely biodegradable, but because it is a fast-growing fungi that thrives in the dark, its production is said to consume far fewer natural resources and emit fewer greenhouse gases, versus that of animal leather. Furthermore, by adjusting the size and shape of the proprietary trays, mycelium can be coaxed to grow into specific shapes and dimensions (e.g. a sneaker or a handbag), thus eliminating the waste associated with cutting animal hides.

Where can you find mycelium leather?

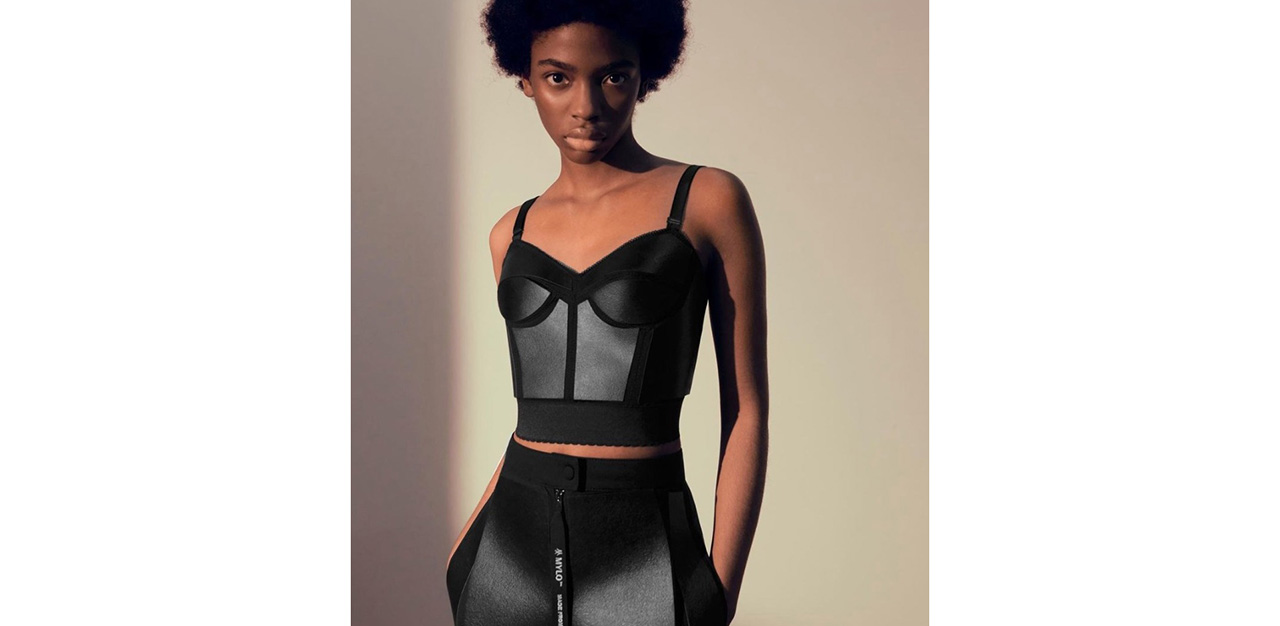

As the technology is still in its infancy, it could be a while before mycelium leather becomes widely available and accessible. Always at the vanguard of sustainable fashion, earlier this year Stella McCartney introduced the world’s first mycelium-based wearables: A jet-black bustier top and coordinated utilitarian trousers, crafted using Bolt Thread’s Mylo Unleather. However, the garments are one-offs and are not available for sale; rather, they serve as a glimpse of what is to come.

We might not have to wait all that long, though, as Hermès announced in March that it is planning to give one of its famed handbags a mushroom makeover. In partnership with California-based startup MycoWorks, the luxury French maison will reimagine its classic Victoria travel bag in an amber-hued mycelium leather called Sylvania, with the model slated to hit the market later this year.

And in mid-April, Adidas broke the news that a Mylo Unleather variation of its iconic Stan Smith sneakers is on the way, where the outer upper, three-stripe logo and heel tab will be made of the mushroom-based material and combined with a natural rubber sole. The Stan Smith Mylo is expected to roll out sometime in 2022.

Microsilk

If you saw a cobweb, you might swat it away without a second thought. But did you know that spider silk (what arachnids use to weave their webs) is actually one of the toughest materials known to man? Five times stronger than steel, but springier than rubber and extremely lightweight, spider silk is one of nature’s wonders.

For decades, scientists have tried to replicate this spidroin fibre in the lab, to little avail. Until Dan Widmaier and his team at Bolt Threads came along, that is. After eight years of painstaking research, including studying hundreds of different spider species like the argiope bruennichi under the microscope, Bolt Threads reached the holy grail, having succeeded in creating a serviceable, scalable, synthetic spider-style silk, dubbed Microsilk.

Stronger than conventional silkworm silk, Microsilk retains the coveted softness, smoothness and lustrousness of the original, in addition to being hypoallergenic, antimicrobial and tear- and water-resistant. What is not to like about that?

How is microsilk made?

Worry not, because no spiders are harmed in the manufacturing of Microsilk. Instead, Bolt Thread’s scientists bioengineer genes that mimic spidroins and implant them in yeast cells. Combined with sugar and water, and left to ferment in large stainless steel tanks, the yeast multiplies and produces silk proteins, which are then extracted, purified and spun into yarn.

Why is microsilk considered sustainable?

Bolt Threads claims that because Microsilk is protein-based, it has the potential to fully biodegrade at the end of its life. Adding to its eco-credentials, Bolt Threads also states that the sugar utilised in Microsilk’s fibre-making process is obtained from renewable resources.

Where can you find microsilk?

As with mycelium leather, Microsilk is still in the research and development phase, but it is only a matter of time before the sustainable fabric becomes commercially available. In March 2017, Bolt Threads debuted a direct-to-consumer, limited-edition range of Microsilk neckties that sold out within minutes, followed later that year by a limited 100-piece run of winter beanies knit from Microsilk and Rambouillet wool, which met with similar success.

Frequent collaborator Stella McCartney also employed Bolt Threads’ biomaterial in two prototype dresses: the first, an asymmetrical gold shift dress designed expressly for a 2017 fashion exhibit at the New York Museum of Modern Art; the second, a white tennis dress in a high-performance blend of Microsilk and cellulose, conceived as part of the 2019 Adidas x Stella McCartney collection.

Bio-leather

Concocted during the Qin Dynasty as a health-boosting elixir, kombucha has enjoyed a meteoric rise in popularity over the last few years, now found everywhere from supermarket shelves to craft cocktail menus to beauty bars. The next frontier in the kombucha craze? Vegan leather footwear.

A sustainable substitute for animal hide, bacterial nanocellulose or bio-leather is derived from the gelatinous microbial mat known as SCOBY (a symbiotic culture of bacteria and yeast), a key ingredient in brewing kombucha tea.

This bio-fabricated textile is the brainchild of a team of Columbia University researchers, spearheaded by material scientist Theanne Schiros and developed in tandem with biomedical engineering professor Helen Lu and PhD student Romare Antrobus.

How is bio-leather made?

Adopting a circular waste-to-resource approach, Dr Schiros sources waste SCOBY from Brooklyn kombucha brewery Om Champagne Tea and feeds it with sugar gleaned from waste streams, such as coffee grounds and leftover fruit. During fermentation, the SCOBY converts the sugar into bacterial nanocellulose, which is then treated with enzymes and tinted with plant-based dyes so that it looks and feels like animal leather.

Why is bio-leather considered sustainable?

A life cycle analysis conducted by Dr Schiros proved that this closed-loop system reduces human toxicity by almost 10,000 times, as compared to chrome-tanned animal leather, and its carbon footprint is up to 97 per cent lower than synthetic PU leather. What is more, once grown, bio-leather will assume the shape of whatever mould it is dried in, meaning that it’s also effectively zero-waste. Oh, and it fully degrades in a domestic compost heap in a matter of months.

Where can you find bio-leather?

Under the Slow Factory Foundation’s One x One incubator programme, Dr Schiros joined forces with Public School New York’s Dao-Yi Chow and Maxwell Osborne to realise a pair of monochrome high-top sneakers made entirely from bio-leather, except the cork and vulcanised rubber soles. Sadly, you cannot buy these kombucha kicks just yet, but we are keeping our fingers crossed that Dr Schiros and her team will figure out how to scale up the production process soon.

Algae fabrics

It sounds like a plot straight out of a horror movie, but in the not-too-distant future, the clothes you wear could very well be alive. Enter algae-infused textiles, which are steadily gaining traction on account of their ability to act as carbon sinks.

As the name implies, these biofabrics tap on a group of photosynthetic autotrophs that belong to the Protista kingdom. To wit, algae.

Harnessing technology to propel the fashion industry forward, a number of designers and scientists are working hand-in-hand to forge groundbreaking materials that lend new meaning to the term ‘organic’. Among these innovations are an algal bioplastic devised by interdisciplinary designer Charlotte McCurdy; a sheer, gauze-like ‘biogarment’ created by Canadian-Iranian designer Roya Aghighi in collaboration with the University of British Columbia; and a living textile coating comprised of algae and cyanobacteria, pioneered by Dian-Jen Lin and Hannes Hulstaert of biotechnology start-up Post Carbon Lab.

How are algae fabrics made?

Most of the designers have kept the specifics under wraps (with good reason, as the majority of us laymen would be unable to comprehend the necessary methodologies).

What Ms McCurdy has disclosed is that, in order to construct her version of bioplastic, marine macro-algae are first exposed to and bound by heat, then poured into custom-made moulds and left to solidify, and finally, overlaid with plant-based wax to improve its resistance to water. Meanwhile, Ms Aghighi has revealed that biogarmentry entails spinning chlamydomonas reinhardtii (a type of unicellular green algae) with nano polymers, and Ms Lin has explained that applying an algal coating to an item of clothing involves embedding microorganisms into porous fibres to render a living layer over the desired textile.

Why are algae fabrics considered sustainable?

As mentioned above, textiles integrated with algae can help purify the air and slash greenhouse gas emissions – when exposed to sunlight, algae sequesters carbon via photosynthesis, an endothermic reaction through which carbon dioxide is absorbed and oxygen is released.

Ms Aghighi also believes biogarmentry can act as a catalyst in transforming our relationship with fashion from one of neglectful consumption to one of empathetic connection, thereby helping to address existing issues of hyperconsumerism. “By making textiles alive, users will develop emotional attachments to their garments,” she told Dezeen. “Since the life cycle of the living photosynthetic textile is directly dependent on how it is taken care of, caring for clothes would regain ascendance as a crucial part of the system.”

Where can you find algae fabrics?

Ms McCurdy’s bioplastic raincoat and Ms Aghighi’s biogarments are currently at the proof-of-concept stage, but the Canadian-Iranian designer has said that she hopes to launch her inventions on the market within the next five to seven years. Likewise, although Post Carbon Lab unveiled a four-piece capsule of unisex apparel during Paris Fashion Week in March, the fruit of a three-way collaboration with French marques DS Automobiles and EgonLab, it appears there are no plans to mass-produce the collection, as it is simply a demonstration of the possibilities offered by algae bio-textiles.

For the time being, your best bet would probably be algae accessories. Together with outdoor apparel label So ILL, Aquaman star Jason Momoa introduced a couple of limited-edition, eco-friendly sneakers back in February (still in stock!), which feature BLOOM algae resin in the insoles as an alternative to petrochemical ethylene-vinyl acetate foam. Kanye West’s Yeezy also incorporates algae-based foam in its futuristic Foam Runner silhouette, if your tastes lean more towards the hypebeast aesthetic.

AIR-INK

Yes, technically, AIR-INK is not a textile. But since it is used on fabrics, it should count too, right? Besides, it is far too interesting to ignore.

Struck by a bolt of inspiration during a conference in India, Graviky Labs’ co-founder Anirudh Sharma began working on the idea of upcycling pollution into printing ink, while he was still a graduate student at MIT. And so, AIR-INK was born.

How is AIR-INK made?

Equipped with Graviky Labs’ trademark KAALINK technology, a retrofit tool is attached to the exhaust pipe of a vehicle, gradually stockpiling soot (and harmful particulate pollutants such as PM 2.5) emitted by the diesel-burning engine as the car is driven around. Once the KAALINK is saturated, the particulates are transferred into carbon banks, passed through a filtration process that removes heavy metals and carcinogens, ground into an ultra-fine powder, and then mixed with solvents to form a certified-safe AIR-INK pigment that can be used in ink, dye or paint as a replacement for petroleum-derived carbon black.

Why is AIR-INK considered sustainable?

Graviky Labs estimates that utilising AIR-INK in lieu of traditional carbon black will lower its ecological footprint by between 50 to 150 per cent – each kilogramme of AIR-INK can mitigate 800 grams of carbon dioxide.

Where can you find AIR-INK?

Celebrity-loved, sustainable label Pangaia just dropped a capsule of luxe loungewear designed by Jenke Ahmed Tailly (stylist to stars like Beyoncé and Kim Kardashian), featuring AIR-INK prints on the label’s signature recycled cotton t-shirts, hoodies and trackpants.